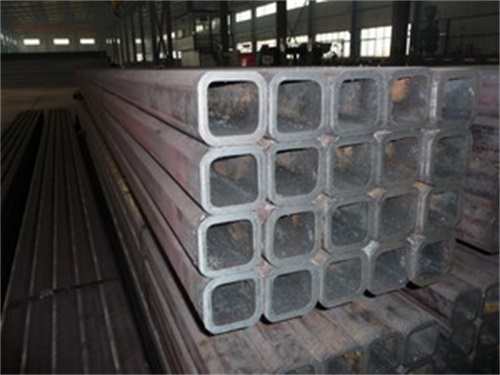

方管的耐磨性

今日方管在近几年在管道中的应用是很大的,可以说是有了巨大的应用。在管道应用中由于大量运输一些粘稠度比较高的液体,所以它独有的耐磨性就体现出来了,那么方管的耐磨性有什么特点呢?

square pipe has been widely used in pipelines in recent years. It can be said that square pipe has great application. In the pipeline application, because a large number of high viscosity liquids are transported, the unique wear resistance of square pipe is reflected. What are the characteristics of wear resistance of square pipe?

1.很好的连接性能:

1. Good connection performance:

方管基材是普通235钢板,保证耐磨钢板具有韧性和塑性,提供抵抗外力的强度,可以采取焊接、塞焊、螺栓连接等多种方式和其他结构进行联系,连接牢固,不容易脱落,连接方式多于其他材料;

square pipe base material is ordinary 235 steel plate, which guarantees the toughness and plasticity of wear-resistant steel plate and provides strength against external forces. It can be connected with other structures by welding, plug welding, bolt connection, etc. The connection is firm, not easy to fall off, and the connection mode is more than other materials.

2.很好的选择性能:

2. Good selectivity:

方管选择不同厚度基材,堆焊不同层数和厚度的合金耐磨层,可以得到不同厚度和不同用途的钢板,大厚度可达到30㎜以上;

square pipe can be welded with different thickness of base material and different layers and thicknesses of alloy wear-resistant layer, and steel plates with different thickness and different uses can be obtained. The maximum thickness can reach more than 30 feet.

3.很好的加工性能:

3. Good processing performance:

方管能够按要求加工成不同规格尺寸,可以进行加工、冷弯成型、焊接、弯曲等,方便使用;可以现场拼焊成型,使维修更换工作变得省时、方便,大大降低工作强度.

square pipe can be processed into different specifications and sizes according to requirements. It can be processed, cold-formed, welded, bended, etc. It is convenient to use. It can be tailor-welded on site, which makes maintenance and replacement work time-saving, convenient and greatly reduces the working strength.

- 抚州矩形管表层处理方式 2021-06-11

- 衡阳无缝方管厂家直销价格 2024-01-13

- 九江方管150~200mm规格加工 2022-10-19

- 景德镇方管硬度 2024-01-13

- 抚州无缝方管的清洗步骤 2020-03-25

- 南昌矩形管的耐腐蚀性是怎样的 2021-05-27

- 岳阳方管价格查询 2024-01-13

- 无缝方管销售价格 可送货上门 2022-10-06

- 抚州方管重量 2024-01-11

- 太原矩形管价格 2020-09-30